Key Configurations

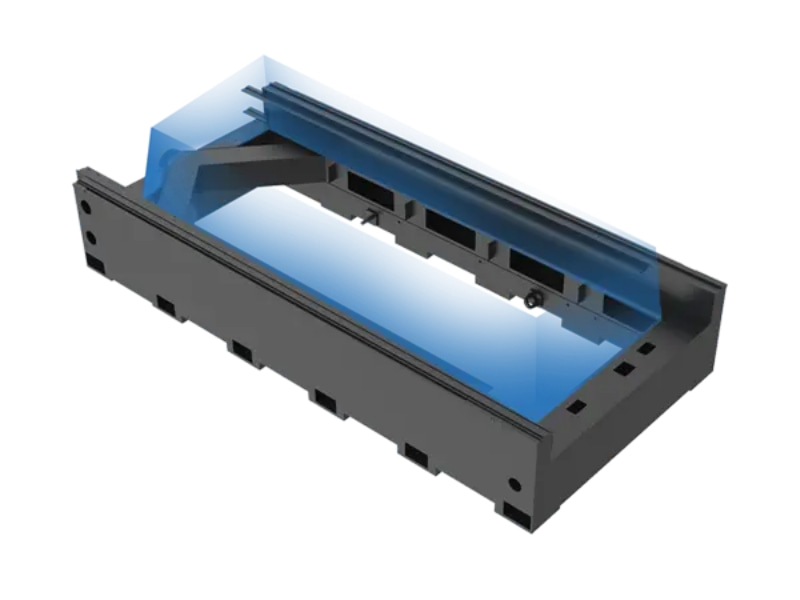

Heavy-load Thermal Isolated Hollow Bed

- High-integrity welded steel construction with 25mm reinforced sidewalls withstands 18-ton dynamic loads

- Stress-relief annealing and secondary aging treatment eliminate 99.7% internal stresses

- Precision-machined on super-sized gantry mills achieving ±0.02mm/m flatness tolerance

- Thermal-isolated hollow design minimizes heat transfer to maintain ±0.05mm positioning accuracy

Intelligent Spiral Vacuum Dust Removal

- Time-sharing vacuum system with automatic air outlet switching and sectional exhaust control

- Back-sealing base design achieves near-zero smoke emission during cutting operations

- Patented spiral airflow technology increases dust capture efficiency by 40% compared to conventional systems

- Standard graphite/copper protection on 8kW+ power configurations prevents material oxidation

Fifth-generation Aviation Aluminum Alloy Beam

- T6 heat treatment maximizes structural strength with hardness rating of HRB 80+

- Solution treatment enhances material plasticity while maintaining ultimate tensile strength

- Topology-optimized design achieves 25% weight reduction vs standard steel beams

- Isotropic material properties ensure uniform dynamic response at 1.5G acceleration

Intelligent Plate Processing

- Exchange table system supports 6000×2000mm plates with <3sec load/unload transition

- Capacitive height sensing maintains 0.15-0.3mm cutting distance across warped materials

- Active exhaust filtration removes 99.8% of particulates from cutting smoke

- Monolithic granite bed with 5µm vibration absorption capability under 2G acceleration

Unified CNC Control System

- Single-interface operation manages both plate nesting and tube programming workflows

- Material recognition AI auto-detects carbon steel/stainless/aluminum and applies optimal parameters

- 4kW/6kW/15kW laser options with dynamic power modulation (±1% energy stability)

- Real-time collision simulation prevents tool interference during complex multi-axis moves