02 Key Configurations

Servo Motor System

- Uses servo motor technology to power the hydraulic pump, reducing energy consumption by approximately 40%

- Increases overall ram operation efficiency by 7-20% for faster cutting cycles

- Maintains hydraulic oil temperature 10-20°C lower than conventional systems

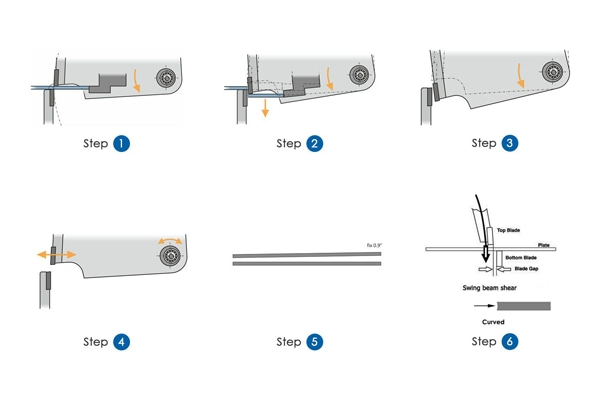

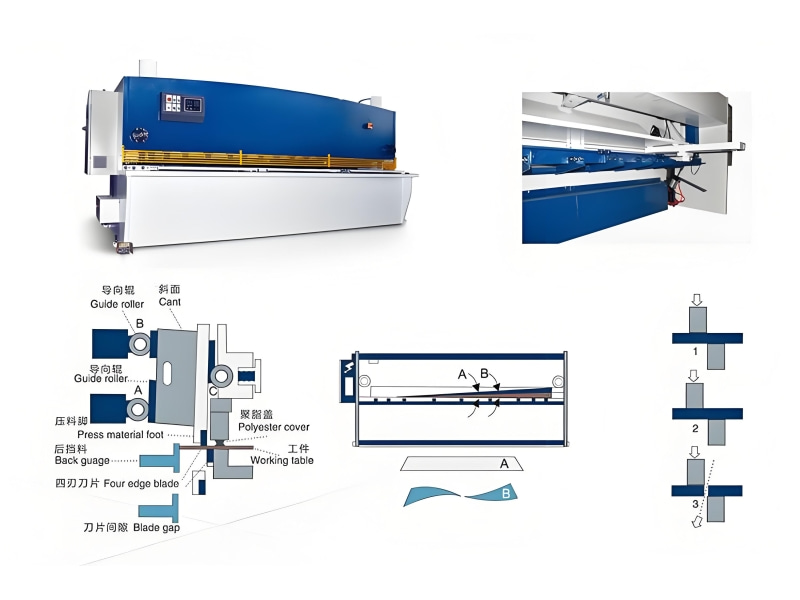

Precision Blade Gap Adjustment

- Patented quick-adjust mechanism changes blade clearance in seconds with tool-free operation

- Digitally controlled gap calibration automatically optimizes clearance for material thickness and type

- Memory presets store frequent configurations for instant recall

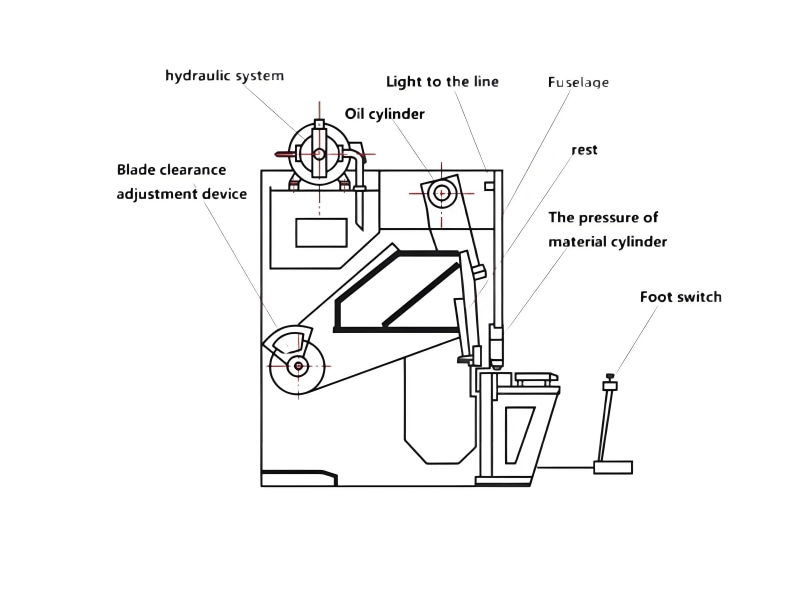

Hydraulic Cutting System

- Integrates Bosch Rexroth servo-proportional valve technology for precision blade force control

- Dual-cylinder synchronization ensures blade parallelism during cutting cycles

- Pressure-compensated flow control maintains consistent cutting speed

- Minimized hydraulic shock through optimized valve acceleration/deceleration

Hydraulic Press Pads

- Position-adjustable pads move along blade-length guides for optimal material coverage

- Automatically apply downward pressure to maintain constant sheet contact

- Deliver high-friction clamping to prevent material shifting during cutting cycles

- Essential for vibration-free shearing and distortion-free results

Safety Guard System

- Full-perimeter protective fencing with optical-grade windows prevents operator access to the shear zone

- Safety interlock system automatically halts blade movement when gates are accessed

- Maintains optimal visibility of cutting operations while ensuring operator protection

- Reinforced steel frame withstands impact and contains flying debris

Hydraulic Power System

- Powered by SUNNY® heavy-duty hydraulic pump – American-engineered reliability for industrial shearing

- Maintains consistent flow rates up to 120 GPM at 3,000 PSI for distortion-free cutting cycles

- Precision-engineered pistons deliver instant blade force for maximum material yield strength

- Self-compensating design optimizes energy efficiency under variable loads