Key Configurations

Dual-Function Processing Unit

- Simultaneous processing capability handles both 6m x 2m plates and Φ25-310mm tubes without tool change

- Auto-switching dual-platform design enables zero-downtime transition between plate and tube cutting modes

- Kinematic thermal compensation maintains ±0.03mm accuracy across 15-40℃ operating range

- Multi-axis interpolation synchronizes tube rotation with X-Y movement for 3D contour cutting

Tube Rotation & Cutting System

- Precision-ground chucks provide 0.01° angular positioning repeatability for complex contours

- Direct-drive rotational axis achieves 120 RPM with ±0.1mm axial runout control

- Auto-centering technology accommodates oval tubes within 2% deformation tolerance

- Collision-adaptive TRA system instantly halts motion upon impact and self-recovers alignment

Intelligent Plate Processing

- Exchange table system supports 6000×2000mm plates with <3sec load/unload transition

- Capacitive height sensing maintains 0.15-0.3mm cutting distance across warped materials

- Active exhaust filtration removes 99.8% of particulates from cutting smoke

- Monolithic granite bed with 5µm vibration absorption capability under 2G acceleration

Unified CNC Control System

- Single-interface operation manages both plate nesting and tube programming workflows

- Material recognition AI auto-detects carbon steel/stainless/aluminum and applies optimal parameters

- 4kW/6kW/15kW laser options with dynamic power modulation (±1% energy stability)

- Real-time collision simulation prevents tool interference during complex multi-axis moves

Wide Pipe Clamping Range

- Round tube clamping range: φ10-φ250mm

- Square tube range: 10×10mm to 220×220mm

- Supports cutting of various profiles including I-beams, channels, angle irons, elliptical tubes, and deformed pipes

- Universal chuck design accommodates both standard and non-standard cross-sections

Pneumatic Roller Support System

- Active workpiece stabilization eliminates deformation during long-tube cutting operations

- Self-leveling rollers adapt to 10-250mm diameters with ±0.05mm vertical positioning accuracy

- Programmable pressure zones apply optimal clamping force for thin-walled and irregular profiles

- Retractable design clears obstruction during plate processing for seamless mode transitions

Wide Processing Range, Can Cut a Variety of Tubes

- Round tube processing: ø15mm-ø220mm diameter

- Square tube processing: 15×15mm to 150×150mm

- Capable of cutting structural profiles including H-beams, I-beams, angle steels, and channels

- Handles specialized tube shapes (drop-shaped, concave, etc.) with 3D laser cutting head

Double Pneumatic Chucks, Ultra-short Tailing

- Front/rear automatic centering with dual-driven rotation maintains perfect synchronization

- Full-stroke front chuck design enables maximum material utilization

- Tailing reduced to 50mm through innovative front chuck avoidance cutting technology

- Precision clamping system ensures zero slippage during high-speed 120 RPM operations

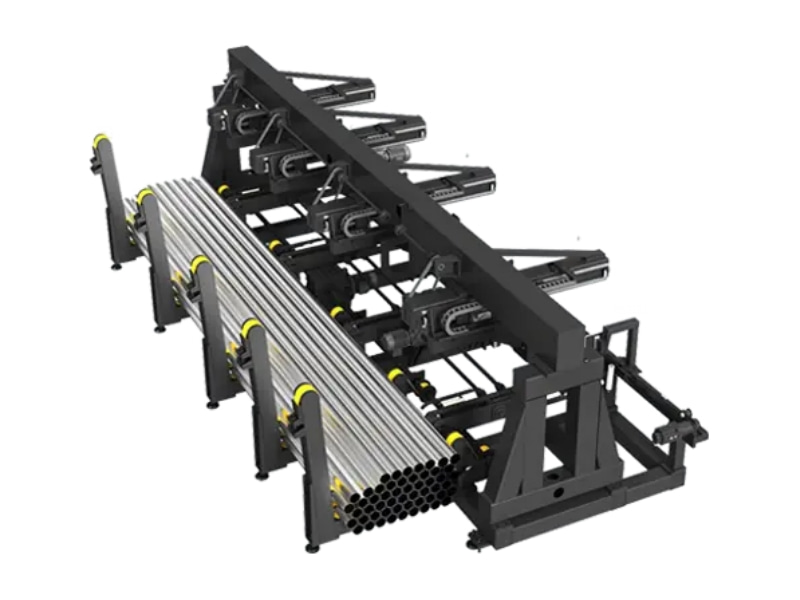

Automatic Loading Equipment (Optional)

- Intelligent transmission mechanism with tube sequencing technology ensures orderly material flow

- 6-clamp roller system eliminates reset cycles between loading operations

- Continuous feeding capability reduces idle time by 40% and increases cutting efficiency

- Auto-alignment technology positions materials within ±0.5mm tolerance