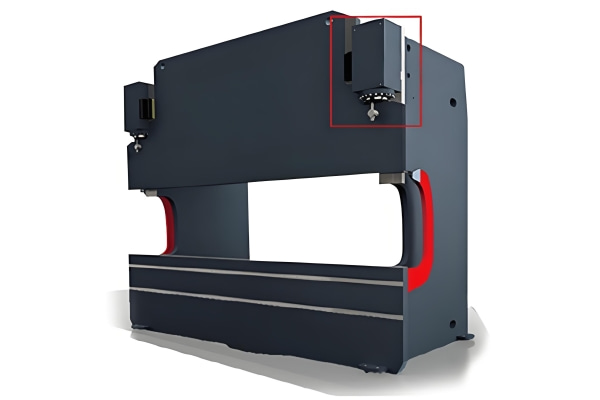

03 Key Configurations

Servo Motor

- Adopts servo motor as the main power source for hydraulic pump, saving energy by about 40%

- Overall efficiency of slider operation increased by approximately 7-20%

- Oil temperature reduced by about 10-20°C

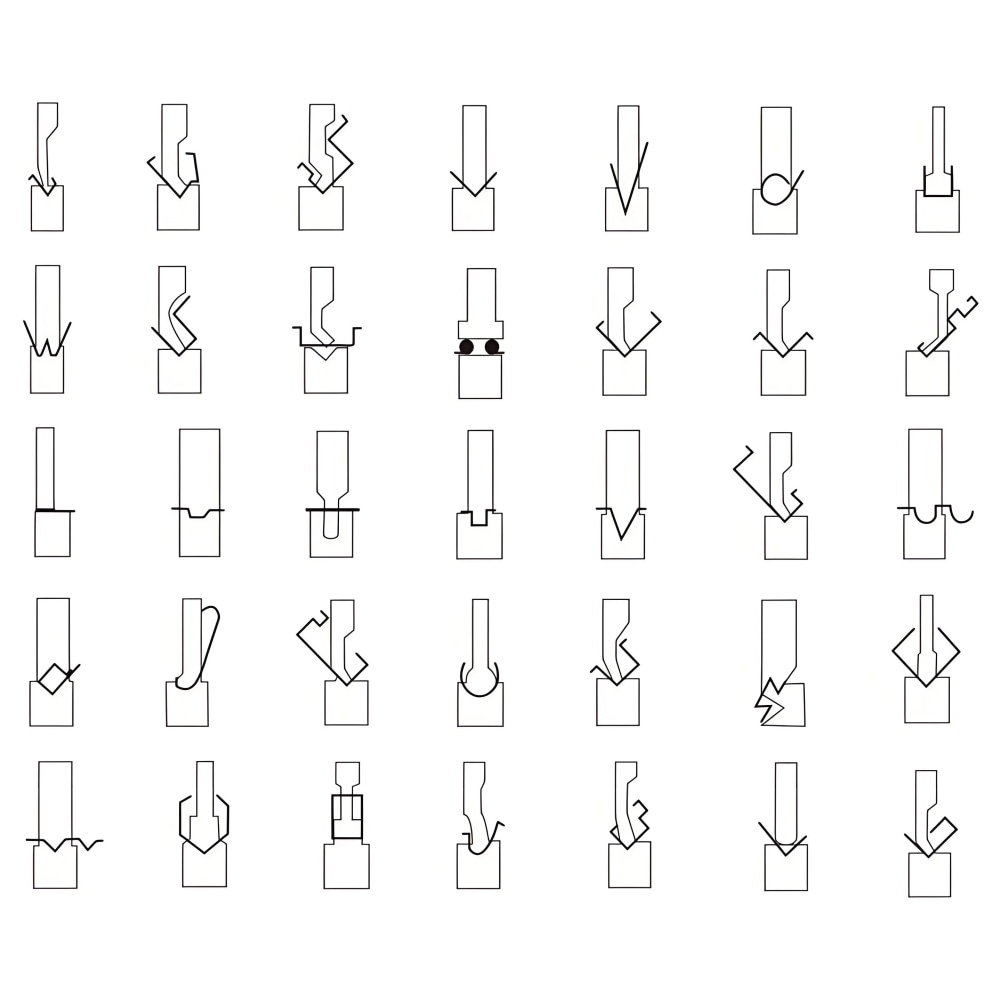

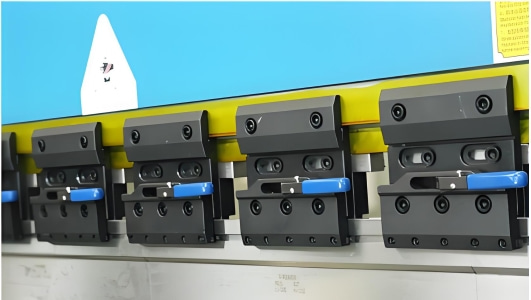

Mold & Quick Fixture

- Equipped with quick mechanical clamping fixtures for rapid and efficient mold replacement or adjustment

- Upper and lower molds configured according to customer's actual processing needs

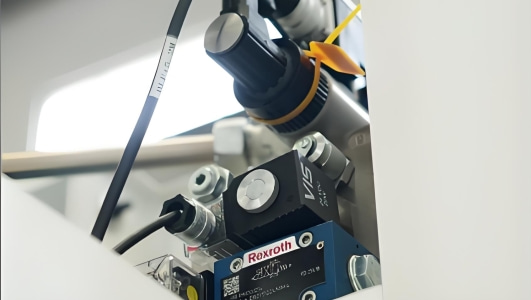

Hydraulic System

- Features Bosch Rexroth servo proportional valve system for stable oil pressure control and sensitive feedback

Mobile Front Support Shelf

- Movable front support bracket moves along linear guides

- Can be parked at any position with rotation and height adjustment functions

- Assists your bending work efficiently

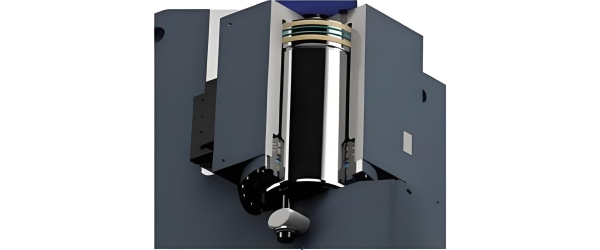

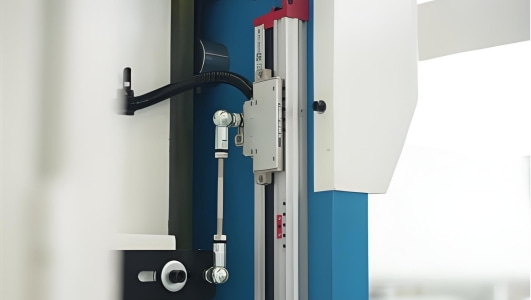

Linear Encoder

- Equipped with Italian GIVI grating ruler displacement sensor

- High displacement detection accuracy and fast response speed

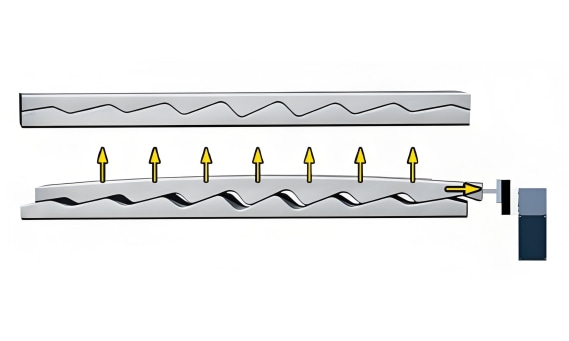

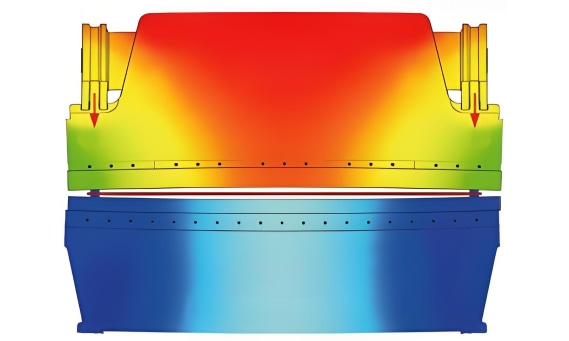

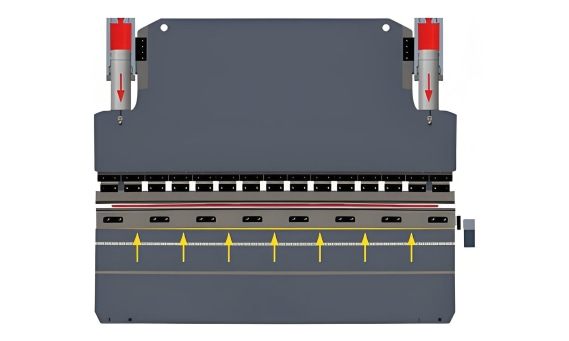

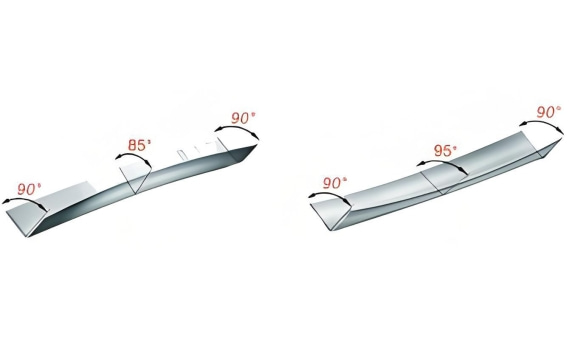

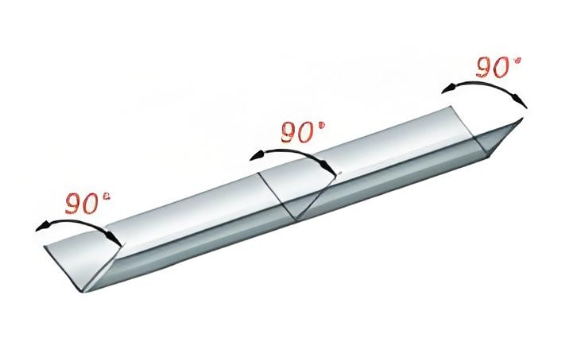

Mechanical Compensation Device

- High-precision wedge compensation device

- Controlled by CNC system for precise compensation

- Ensures high-quality bending accuracy

Electrical Components

- Uses Schneider original imported components for stability, durability and long service life

- Whole machine adopts Estun adaptive electrical box assembly with strong anti-interference ability and stable electrical performance

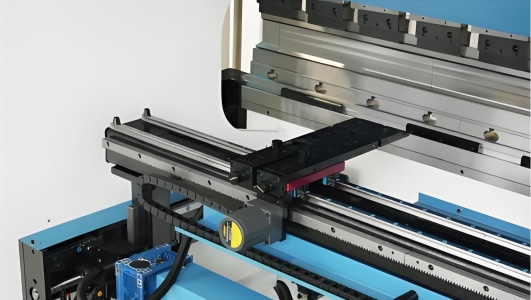

Stable Back Gauge System

- Imported ground ball screw drive and linear guide for precise positioning

- Double linear guide structure on the beam ensures accurate positioning

- Equipped with precision multi-level gauge fingers to expand positioning range

- Makes bending more convenient and efficient