Key Configurations

Rigid Frame Structure

- Granite composite bed ensures vibration absorption within 5µm during 2G acceleration

- Thermally stabilized steel framework maintains ±0.1mm positional accuracy across 25℃ operating range

- Monolithic weld-free construction eliminates stress points for micron-level cutting precision

- Kinematic mounting system compensates for thermal expansion/contraction

Atlanta Precision Drive

- Proprietary ground racks deliver 8μm/m pitch accuracy - 30% tighter tolerance than industry standard

- Helical pinions with P4-class bearings reduce friction losses by 45% for energy-efficient operation

- Monolithic preloaded assembly achieves ±0.005mm/m positioning repeatability at 120m/min traverse

- Thermal-compensated mounting maintains alignment within 0.01mm across 15-40℃ operating range

CypCut Intelligent Control System

- Custom CypCut software enables single-click nesting optimization for sheet layouts

- Intuitive touch interface with drag-and-drop CAD/CAM integration (DXF/DWG/STEP)

- Real-time power modulation maintains ±1% energy density across cutting paths

- Adaptive Process Control® automatically adjusts for 200+ material profiles

- Multi-axis simulation previews full cutting cycles before execution

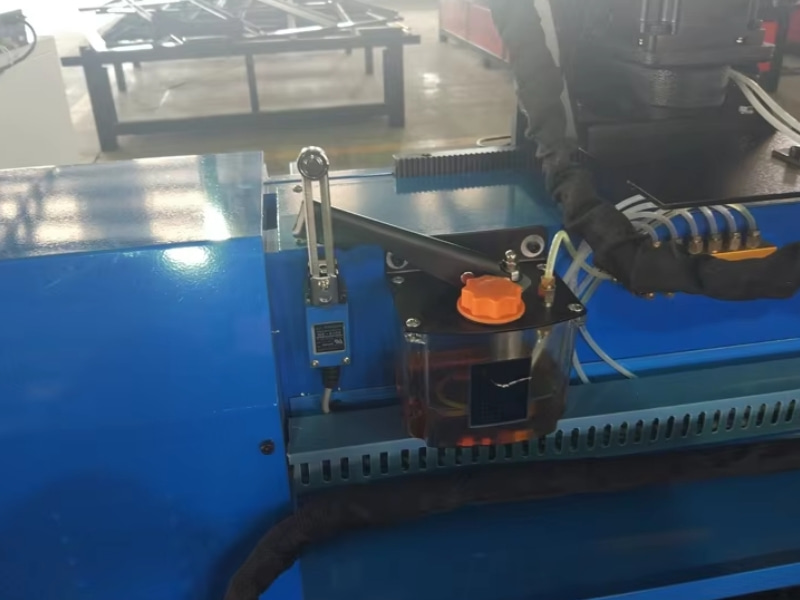

RAYTOOLS Precision Cutting Heads

- IP65-rated dustproof encapsulation eliminates optical path contamination, enabling zero-downtime operation in harsh workshop environments.

- Dynamic Zero-Point Calibration unifies focal positions across materials, eliminating manual parameter adjustments for mixed-batch processing.

- Direct-cooled nozzle assembly with corrosion-resistant channels maintains thermal stability during non-stop 24/7 cutting cycles.

- Collision-adaptive TRA system instantly halts motion upon impact and auto-resets with micron-level repeatability, minimizing crash damage.